HPP for Energique Raw Veterinary Diets

All Energique Raw Veterinary Diets products are subjected to High Pressure Processing (HPP).1 HPP is a scientifically validated method to increase microbial safety of (human) food. Cold, isostatic pressure (equally applied on all sides) eliminates harmful bacteria, while preserving the full nutritional value and sensory quality. This means that the products can safely be used for dogs with specific disease conditions.

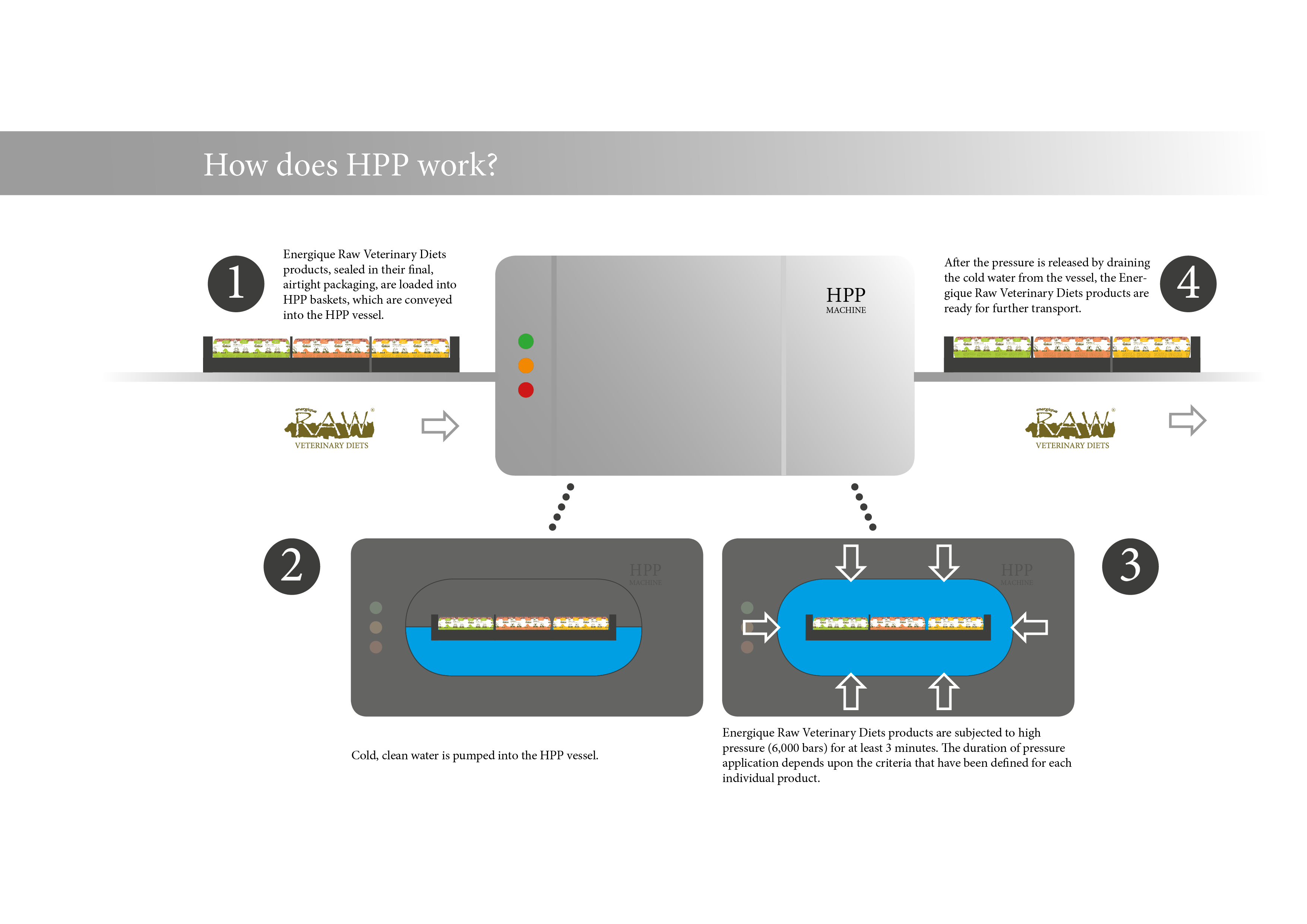

Below, an infographic depicts a simplification of the technology behind High Pressure Processing (HPP).

Curious about HPP, High Pressure Processing?

1. Tananuwong, K., Chitsakun, T., Tattiyakul. (2012) Effects of high‐pressure processing on inactivation of Salmonella Typhimurium, eating quality

and microstructure of raw chicken breast fillets. J Food Sci, 77(11), 321‐327.

FAQ

HPP (High Pressure Processing) is a scientifically unique and validated method to increase microbial safety of (human) food. Cold, isostatic pressure (equally applied on all sides) eliminates harmful pathogens, while preserving the full nutritional value and sensory quality. This process is executed at refrigerator temperature to ensure minimal denaturation of proteins and minimal damage to other nutrients. All Raw Veterinary Diets are exposed to this unique process in their final packaging, to prevent recontamination.

The following websites can provide you more information:

Avure Technologies website: www.avure.com

Illinois Institute of Technology website: www.iit.edu

American Pasteurization Company website: https://www.americanpasteurizationcompany.com

HPP affects the products at cell level. Harmful (pathogenic) bacteria such as Salmonella, E.coli 0157: H7 and Listeria Monocytogenes are single-celled organisms that may be present in raw meat. HPP destroys the cell wall of these organisms. HPP has no effect at the molecular level. As a result, nutrients such as proteins, enzymes, prebiotics and vitamins and minerals are not affected by HPP. HPP ensures a microbially much safer fresh meat meal while the nutritional value, vitamins and minerals, taste and color are hardly affected!

High pressure is a natural process. More than a century ago, scientists discovered that harmful bacteria found on land (sea level) could not survive when brought to deep sea level (very high water pressure). In the last decades, this phenomenon has been further developed so that we now have a scientifically validated and natural way to eliminate harmful pathogens while retaining enzymes, nutritional integrity and taste.

No! HPP has little to no influence on the naturally present enzymes in the diet.

Enzymes are very resistant to high pressure. Many enzymes in our food remain active up to a temperature of 60-80 degrees. The high pressure in the HPP process is achieved by pumping cold water (4 degrees) into a vessel, which is subsequently pressurized up to 6000 bar for several minutes. Due to this high pressure the temperature rises slightly. Because the treatment lasts only 3 minutes and the products are just above the freezing point at the start of the treatment, the water temperature will not exceed 25-30 degrees during the process. This means that the products will retain their nutritive and sensory value after the HPP process.

High pressure is a natural process. More than a century ago, scientists discovered that harmful bacteria found on land (sea level) could not survive when brought to deep sea level (very high water pressure).

In the last decades, this phenomenon has been further developed so that we now have a scientifically validated and natural way to eliminate harmful pathogens while retaining enzymes, nutritional integrity and taste.